Even good stuff breaks. When Paul Allen received a pair of auctioned Co-Hog Porsche 956's from the Hank Hammer collection, they were damaged, so he sent them home for restoration.

The cast edition of the Co-Hog Porsche 956/962 series with properly scaled wing supports did not provide enough gluing area for solid wing attachment or to protect against the inevitable sharp knocks. Wings popped off and supports were broken.

Thirty-nine years on display and a ride in a shipping container from Hawaii to Texas had left the pair chipped and dirty as well, so there was plenty to work on.

This is the fully restored #7 Newman example with its 1984 and 1985 Le Mans winning livery. It's 53/150 FE and was made for Hank in December of 1987.

The rear view shows the revised, beefed-up wing supports that should do a better job hanging onto the wing.

The second 956 is 1/150 FE, made in February of 1985 for Hank. With #8 Marlboro livery the 1:1 version finished 6th at Le Mans in 1984. It is the only Marlboro 956 Co-Hog made.

The Marlboro graphics are sparse as my original intention was for the graphics to be the essence of the actual liveries just as the forms evokes the shape of the car without replicating them. After completing only four Artist's Proofs and about 10 pieces, I switched to adding more detailed liveries.

That required a huge amount of additional effort. I drew up, created and applied all of the graphic elements one color at a time. Many of the finished pieces were customized with specific company logos and other details.

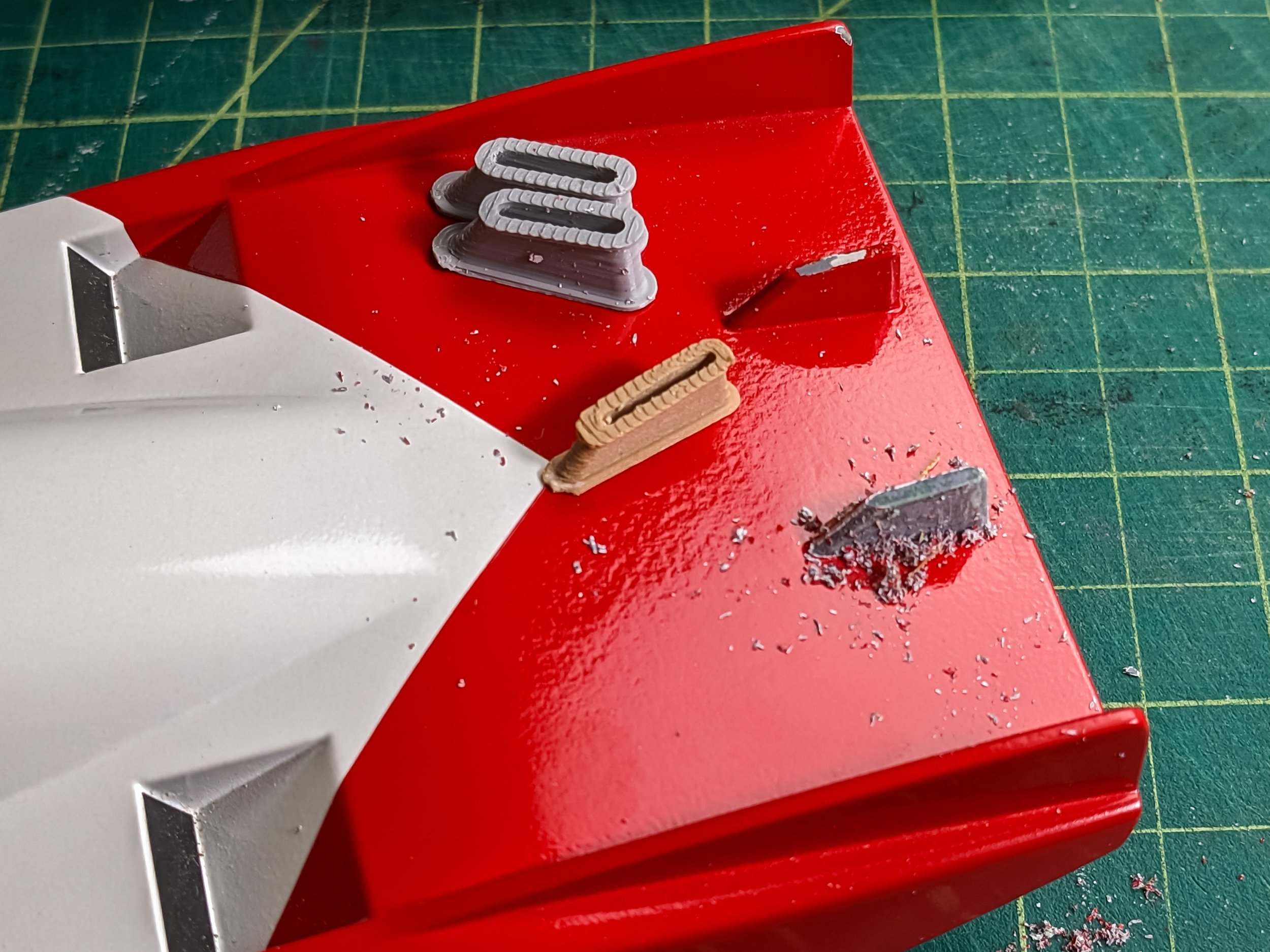

This is the aftermath of various percussive altercations over the decades. The Marlboro car was missing its wing and the Newman car wing was adrift after losing an entire support.

I designed new wing supports to fully encapsulate the original struts and provide additional gluing surface both top and bottom. They slip over the original cast supports. I originally 3D printed them using 100% PLA.

The broken off strut was additionally supported internally with two brass posts.

PLA with 40% wood was used for the final pieces since it was much less stringy and easier to work with. Each wing support is only about 0.670" (17 mm) long and 0.270" (7 mm) tall, making them quite tedious to fill and sand.

The existing wing supports were carefully stripped of existing paint and notched (visible in the previous photo with green circles) to allow the new wing supports to be properly positioned. There was plenty of external and internal surface to bond with.

After several priming, glazing, and sanding cycles, new wings and supports were ready for final priming, sanding, and painting.

The repairs should last a few more decades!